Moving bulk liquids across Namibia is a significant undertaking. If you manage logistics between Walvis Bay and the inland industrial hubs, you are well-versed in the challenges: vast distances, intense heat and the uncompromising need for product safety.

While many operations rely on traditional drums and IBCs, there comes a point where growth demands a more efficient approach. Here is why many Namibian businesses are transitioning to T11 ISO tanks to streamline their supply chains.

The Efficiency of Scale

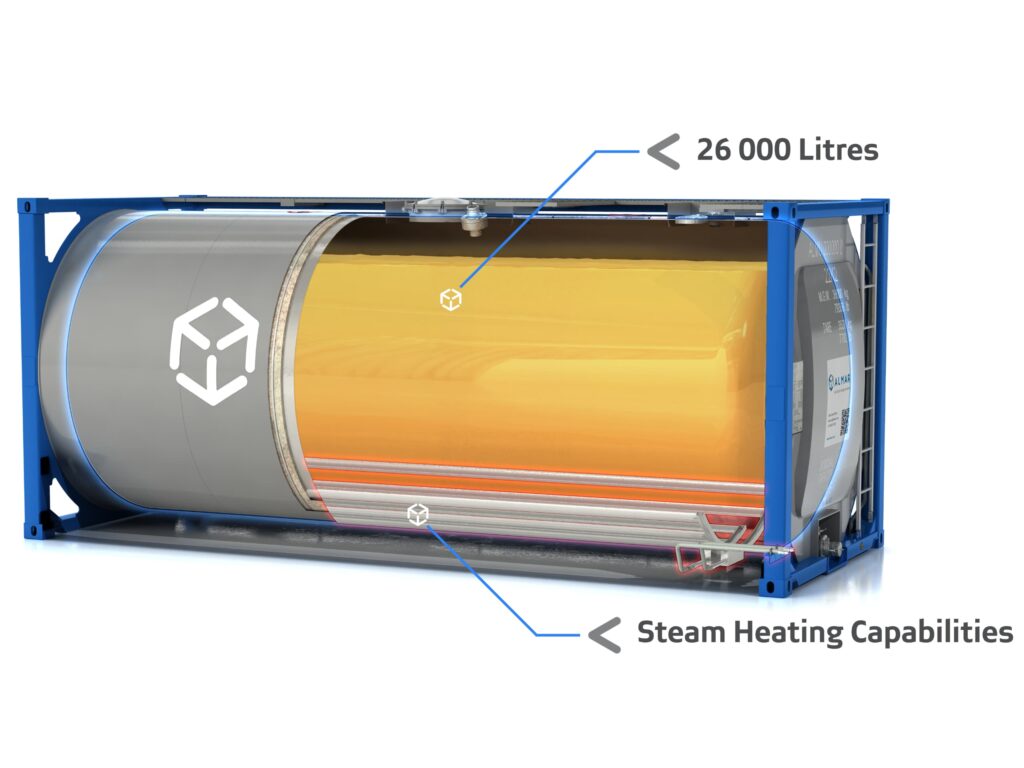

There is a practical simplicity to a drum – until you have to manage 130 of them. That is roughly what it takes to match the volume of a single T11 ISO tank, which holds approximately 26,000 litres.

Consider the cumulative “administrative” burden of 130 drums: 130 seals to inspect, 130 labels to track and 130 individual risks for a leak or spill. Transitioning to a single tank replaces a fragmented logistical process with one streamlined move. It significantly reduces manual labour and more importantly, minimizes the margin for error.

Performance in the Namibian Climate

The Namibian sun is unforgiving, and managing bulk liquids in this environment requires the right equipment. Our T11 ISO tanks are the industrial “workhorse” for a reason. While they aren’t refrigerated units for highly temperature-sensitive perishables, they are engineered with high-performance to protect your cargo from external elements and dust storms.

For products that require a bit more help – like thicker oils or resins that might thicken in cooler transit – our T11 tanks feature built-in steam heating capabilities. This allows for “painless pours,” ensuring your product is at the ideal viscosity for discharge as soon as it reaches the site. It’s a specialized, reliable solution for industrial and food-grade liquids, providing a level of security that traditional packaging simply cannot match.

A Commitment to Sustainability

In today’s mining and industrial landscape, sustainability is an operational necessity.

Drums and IBCs frequently result in significant waste; they are difficult to clean thoroughly and even harder to dispose of responsibly within remote regions.

ISO tanks are designed for a lifespan of several decades. They are professionally cleaned, rigorously tested and redeployed continuously. This “circular” approach to bulk liquid storage is not only environmentally responsible but also ensures your site remains free of the clutter and waste associated with single-use containers.

Finding the Strategic Fit

Drums will always have a place for small-scale, niche deliveries. However, for organizations looking to scale safely and improve their cost-per-litre, the ISO tank is a strategic asset for logistics.

If you are weighing your options and would like to discuss the logistics of your specific site, we would welcome the conversation. We are here to help you move your liquid from A to B with efficiency and peace of mind.

Let’s talk logistics. Get in touch to see how our ISO Tanks can simplify your next move.