Reefer containers play a critical role in storing temperature sensitive goods, ensuring they remain fresh and undamaged. However, incorrect packing can lead to temperature fluctuations, uneven cooling and product spoilage.

To get the most out of your reefer container, proper loading techniques must be followed.

Why It Matters:

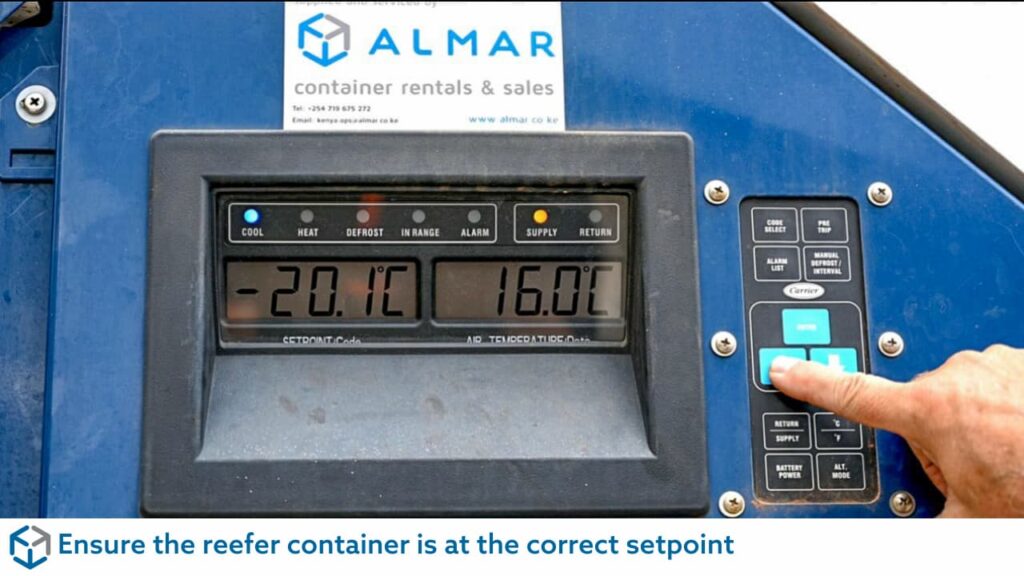

Reefer containers are designed to maintain temperature, not to cool down products from ambient temperatures. If warm goods are loaded, it can take longer to reach the desired temperature, affecting product quality.

Best Practices:

Why It Matters:

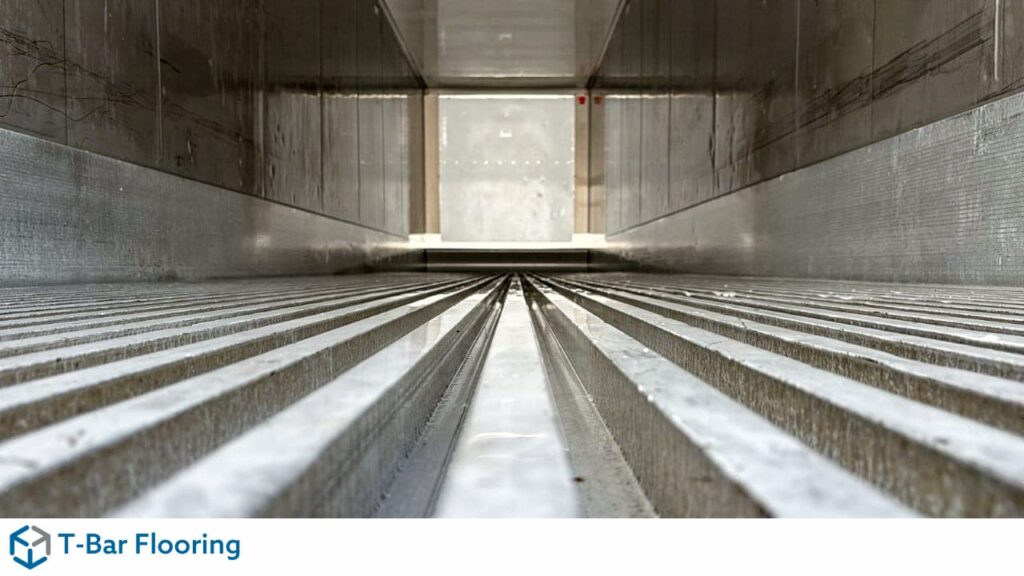

Reefers rely on continuous airflow to maintain a consistent temperature. Blocking air circulation can create hot spots and uneven cooling.

Best Practices:

Frozen Goods

Chilled Goods

Contact us for reliable cold storage solutions tailored to your business needs.